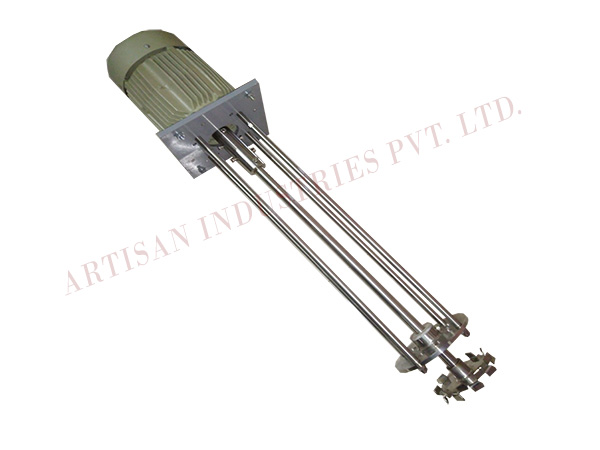

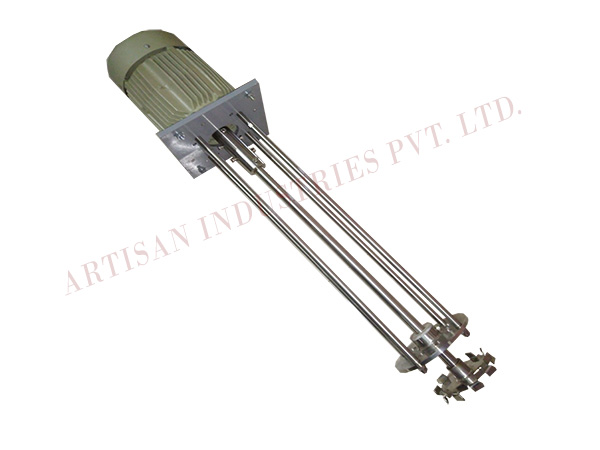

Top Entry Disperser

Artisan Tank-Top High-Speed Disperser is a compact, efficient mixing solution designed to mount directly on top of a processing tank or vessel. This space-saving design is ideal for operations with limited floor space while still delivering high-performance dispersion and mixing capabilities. The disperser features a high-shear saw-tooth blade that rapidly disperses powders and solid materials into liquids, ensuring uniform particle size and consistent product quality. Commonly used in industries such as paints, inks, coatings, and chemicals.

Its direct-mount configuration reduces the need for additional support structures and simplifies cleaning and maintenance. Available in various sizes to fit standard or custom tanks. The tank-top high-speed disperser is an ideal choice for manufacturers seeking efficient, reliable, and space-saving mixing solutions.

Models & Data Sheet

Top Entry Disperser for Non-Pressure Vessel

| Model | Motor Power (HP) | Rotation Speed @ 50 Hz (RPM) | Suggested Capacity (L) |

| TED-N1 | 1 | 1500 | <50 |

| TED-N2 | 2 | 1500 | <75 |

| TED-N3 | 3 | 1500 | <100 |

| TED-N5 | 5 | 1500 | <200 |

| TED-N7.5 | 7.5 | 1500 | <300 |

| TED-N10 | 10 | 1500 | <500 |

| TED-N15 | 15 | 1500 | <750 |

| TED-N20 | 20 | 1500 | <1000 |

| TED-N25 | 25 | 1000/1500 | <1500 |

| TED-N30 | 30 | 1000/1500 | <2000 |

| TED-N40 | 40 | 1000/1500 | <2500 |

| TED-N50 | 50 | 1000/150 | <3000 |

Top Entry Disperser for Pressure Vessel

| Model | Motor Power (HP) | Rotation Speed @ 50 Hz (RPM) | Suggested Capacity (L) |

| TED-P1 | 1 | 1500 | <50 |

| TED-P2 | 2 | 1500 | <75 |

| TED-P3 | 3 | 1500 | <100 |

| TED-P5 | 5 | 1500 | <200 |

| TED-P7.5 | 7.5 | 1500 | <300 |

| TED-P10 | 10 | 1500 | <500 |

| TED-P15 | 15 | 1000/1500 | <750 |

| TED-P20 | 20 | 1000/1500 | <1000 |

| TED-P25 | 25 | 1000/1500 | <1500 |

| TED-P30 | 30 | 1000/1500 | <2000 |

| TED-P40 | 40 | 1000/1500 | <2500 |

| TED-P50 | 50 | 1000/1500 | <3000 |

Specifications & Key Features

- Motor Power (range) — Available from 1.5 kW to 75 kW+ (2–100 HP) to suit lab, pilot and large production vessels.

- Speed Range & Control — Stepless control typically 50–3000 RPM with VFD for precise shear and gentle mixing profiles.

- High Torque Gearbox — Helical/planetary gearbox options delivering high torque at low speeds for viscous and high-load applications.

- Top-Entry Shaft & Impellers — Hardened stainless-steel shaft (Ø 30–100 mm) with interchangeable impellers (turbine, anchor, gate, high-shear rotor/stator).

- Mounting & Flange Interface — Standard top flange or skirt-mounted head for direct vessel installation; anti-vibration mounts and torque arm options.

- Sealing Options — Mechanical seals, stuffing box, or pressurized gland arrangements with barrier/flush for abrasive or sanitary services.

- Wetted Materials & Finish — SS316/SS316L wetted parts, sanitary polish options, and special coatings available for corrosive or food/pharma use.

- Instrumentation & Controls — Integrated control panel/PLC, torque/load monitoring, soft-start, emergency stop, and optional automated speed/position presets.

- Serviceability & Safety — Modular head design for easy removal, greaseable bearings, isolation flanges, guard/interlocks and compliant with CE/UL standards.

- Applications & Performance — Optimized for large-volume dispersion, emulsification, homogenization and heat transfer in paints, coatings, adhesives, cosmetics, food and pharmaceutical processes; available with sanitary and ATEX variants.

Advantages

- Efficient high-volume mixing — Ideal for large tanks and continuous production with uniform dispersion and faster processing.

- Powerful torque & speed control — Handles low to high viscosity materials with smooth operation through VFD control.

- Easy integration & installation — Mounts directly on tank tops, saving floor space and simplifying plant layout.

- Low maintenance & durable design — Robust gearbox, stainless construction, and accessible components ensure long service life.

- Versatile process capability — Suitable for dispersion, emulsification, and homogenization across chemical, paint, adhesive, and cosmetic industries.

Applications

- Paints & Coatings — Effective dispersion of pigments, fillers, and resins for smooth, consistent product quality.

- Adhesives & Sealants — Uniform blending of polymers, additives, and thickeners for stable bonding formulations.

- Cosmetics & Personal Care — Mixing creams, lotions, gels, and emulsions with smooth texture and homogeneity.

- Chemicals & Petrochemicals — Processing emulsions, suspensions, and polymer dispersions in large-scale reactors.

- Food & Pharmaceutical — Hygienic mixing of sauces, syrups, and liquid formulations under sanitary conditions.