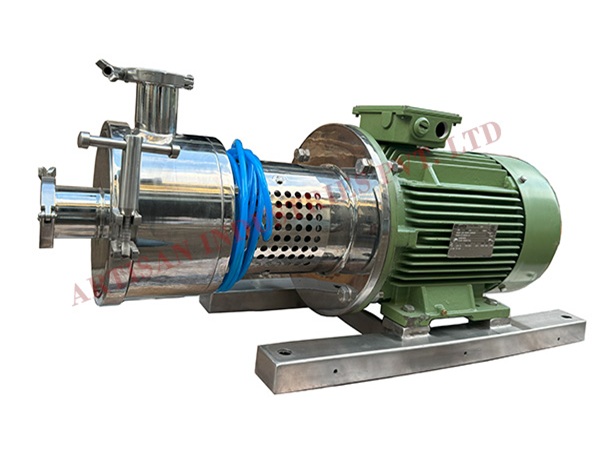

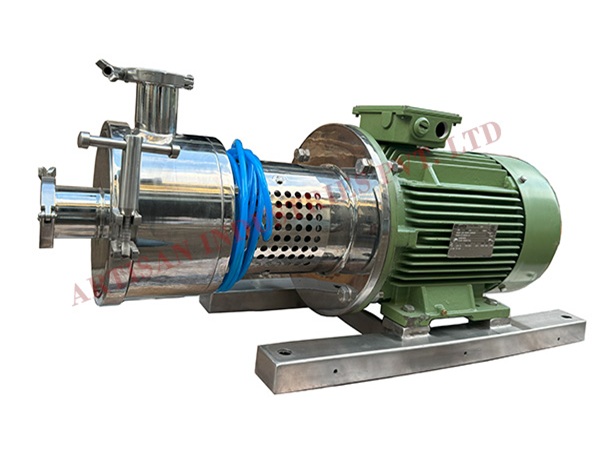

Inline Homogenizer

Artisan Inline Homogenizer is engineered for seamless integration into production lines, delivering continuous high-shear mixing, emulsifying, and particle size reduction. Utilizing a durable rotor-stator design with SS316L contact parts, it achieves micron-level homogenization and ensures consistent product quality. Ideal for pharmaceutical, cosmetic, food, and chemical industries, it enhances stability and texture without compromising throughput.

Featuring adjustable speed and pressure settings, the system supports flow capacities up to 1,00,000 LPH. Its hygienic, CIP/SIP-ready design reduces maintenance downtime while guaranteeing contamination-free processing. With user-friendly controls, advanced automation options, and robust construction, this inline homogenizer optimizes production efficiency and scales effortlessly from pilot to industrial manufacturing.

Models & Data Sheet

| Model | Motor Power (HP) | Rotation Speed @50 Hz (RPM) | Flow Rate @1cPs (m³/h) |

| IH-1 | 1 | 3000 | 3 |

| IH-2 | 2 | 3000 | 5 |

| IH-3 | 3 | 3000 | 10 |

| IH-5 | 5 | 3000 | 20 |

| IH-7.5 | 7.5 | 3000 | 30 |

| IH-10 | 10 | 3000 | 35 |

| IH-15 | 15 | 3000 | 50 |

| IH-20 | 20 | 3000 | 65 |

| IH-25 | 25 | 3000 | 80 |

| IH-30 | 30 | 1500/3000 | 90 |

| IH-40 | 40 | 1500/3000 | 95 |

| IH-50 | 50 | 1500/3000 | 100 |

2D Design/Drawing

Specification

- Capacity Range: Available from laboratory to large-scale industrial models (5 LPH to 20,000 LPH).

- Motor Power: Heavy-duty motor from 1 HP to 50 HP for consistent high shear performance.

- Material of Construction: All contact parts made from SS 304 / SS 316 / SS 316L for corrosion resistance and hygiene.

- Rotor–Stator Assembly: Precision-engineered multi-stage design for uniform particle size reduction.

- Seal Type: Fitted with mechanical seal with cooling arrangement to prevent leakage and overheating.

- Mounting Type: Skid-mounted or inline pipeline design for easy integration with existing process systems.

Key Features

- High Shear Efficiency: Ensures rapid mixing, emulsifying, and homogenizing for uniform product consistency.

- Continuous Operation: Designed for inline processing without batch interruption, saving time and energy.

- Compact Design: Space-saving construction allows easy installation in existing production lines.

- Easy Maintenance: Quick disassembly of rotor–stator system for fast cleaning and servicing.

- Energy Efficient: Optimized motor and rotor design minimize power consumption during high-speed operation.

- Hygienic Construction: Built with smooth, crevice-free stainless steel surfaces to meet sanitary processing standards.

Advantage

- Improved Product Quality: Delivers fine, uniform emulsions and dispersions with consistent particle size.

- Reduced Processing Time: Continuous high-shear mixing cuts down production cycles significantly.

- Enhanced Efficiency: Eliminates the need for recirculation or multiple passes in many applications.

- Easy Integration: Can be directly installed in existing pipelines or process systems without major modification.

- Low Maintenance Cost: Durable construction and minimal moving parts reduce wear and maintenance frequency.

- Scalable Performance: Suitable for laboratory trials to full-scale industrial production with consistent results.

- Operator Friendly: Simple operation with optional automation and safety interlocks for user convenience.

Application

- Pharmaceutical Industry: For preparing emulsions, syrups, ointments, and suspensions with uniform texture.

- Cosmetic & Personal Care: Ideal for creams, lotions, gels, shampoos, and conditioners.

- Food & Beverage Processing: Used for sauces, dressings, dairy products, flavor emulsions, and beverages.

- Chemical Industry: For producing paints, resins, detergents, emulsions, and dispersions.

- Biotechnology & Laboratory Use: Suitable for cell disruption, sample preparation, and fine emulsification.

- Petrochemical Industry: Used in lubricant blending, wax emulsions, and fuel additive preparation.

- Adhesives & Coatings: Ensures consistent mixing of glues, coatings, sealants, and polymer emulsions.