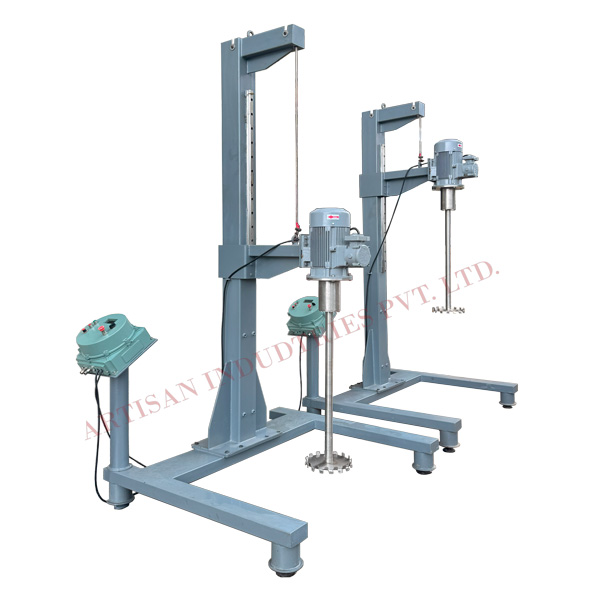

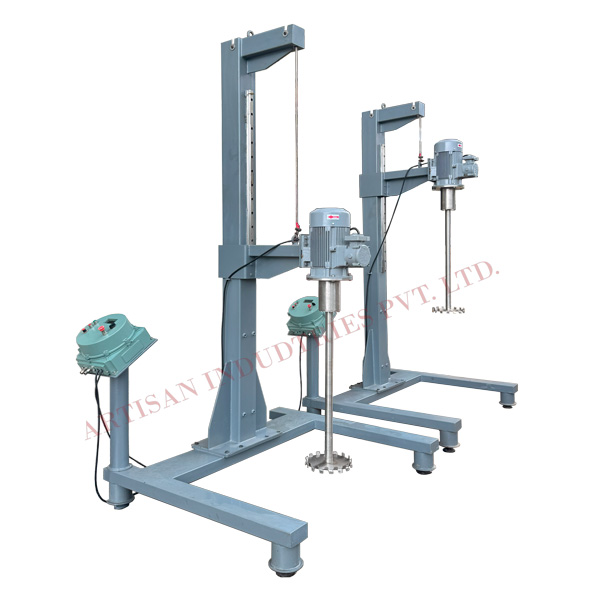

High Speed Disperser- Manual Lifting

Artisan Manual Lifting High-Speed Disperser is a versatile and cost-effective solution designed for efficient mixing, dispersing, and homogenizing of low to medium viscosity materials. Ideal for industries such as paint, coatings, adhesives, and chemical processing, this disperser features a robust motor and high-speed impeller that generate strong shear forces, ensuring uniform particle distribution and improved product quality. The manual lifting mechanism provides easy vertical adjustment of the dispersing head, allowing precise control over mixing depth and operation for different batch sizes.

The Manual Lifting High-Speed Disperser low maintenance requirements and flexible customization options, this disperser offers a reliable and economical solution for manufacturers seeking consistent results and improved process efficiency.

Models & Data Sheet

| Model | Motor Power (HP) | Rotation Speed @ 50 Hz (RPM) | Suggested Capacity (L) |

| DML-1 | 1 | 1500 | <50 |

| DML-2 | 2 | 1500 | <75 |

| DML-3 | 3 | 1500 | <100 |

| DML-5 | 5 | 1500 | <200 |

| DML-7.5 | 7.5 | 1500 | <300 |

| DML-10 | 10 | 3000 | <500 |

| DML-15 | 15 | 1500 | <750 |

| DML-20 | 20 | 1500 | <1000 |

Specifications & Key Features

- Motor Power (range) — Available from 1 HP to 100 HP to suit laboratory to production-scale mixing.

- Speed Range — High-speed shaft with stepless control typically 500–3600 RPM (typical working 800–3000 RPM) for low- to high-shear processes.

- Shaft / Blade Sizes — Hardened stainless-steel shaft (Ø 25–50 mm) with interchangeable dispersion blades (anchor, toothed, saw-tooth, turbine).

- Manual Lifting Mechanism — Smooth, robust manual crank or geared handwheel with counterbalance for safe, precise vertical positioning and easy height adjustment.

- Construction & Wetted Parts — SS304/SS316 wetted components or optional food-grade finishes; powder-coated carbon-steel frame for industrial durability.

- Mount & Clamping — Heavy-duty clamp with quick-lock mechanism and safety pin to secure head at any height; anti-vibration mount for stable operation.

- Controls & Safety — Onboard control panel with start/stop and emergency-stop; mechanical safety guard over blade and limit switches to prevent accidental lowering.

- Cooling & Duty Cycle — Designed for continuous or intermittent duty with optional ventilation/cooling for extended high-load runs.

- Maintenance & Serviceability — Easily accessible gearbox and shaft seals, greaseable bearings, replaceable blades and seals for low downtime.

- Applications & Compliance — Ideal for paints, coatings, inks, adhesives, cosmetics and food suspensions; optional CE/UL compliance and customizable options (VFD, stainless column, splash cover).

Advantages

- Precise height control — Counterbalanced handwheel/crank allows repeatable blade positioning for consistent mixing quality.

- Lower capital & simple operation — More affordable than motorized lifts; easy for operators to use with minimal training.

- Versatile processing — Handles a wide viscosity range with interchangeable blades and broad speed capability.

- Robust, low-maintenance design — Stainless wetted parts, greaseable bearings and accessible seals reduce downtime.

- Safe & compact footprint — Mechanical safety stops and compact frame fit small workshops and pilot labs without complex installation.

Applications

- Paints & Coatings — Rapid dispersion of pigments and fillers for uniform color, gloss and stability.

- Inks & Printing Pastes — Fine particle wetting and de-agglomeration for smooth, clog-free inks.

- Adhesives & Sealants — Efficient blending of resins, fillers and tackifiers for consistent bond strength.

- Cosmetics & Personal Care — Emulsifying creams, lotions and gels; safe for small-batch R&D and production.

- Food & Specialty Chemicals — Mixing sauces, pastes, and suspensions (non-hazardous) plus lab/pilot formulations.