High Shear Batch Mixer- Manual Lifting

Artisan High Shear Batch Mixer with Manual Lifting is expertly designed to provide efficient, uniform mixing, emulsifying, and dispersing of viscous materials. Equipped with a robust manual lifting system, it enables easy height adjustment for versatile operation and ergonomic handling. This mixer delivers high shear forces to reduce particle size and create stable, homogeneous batches, ideal for pharmaceutical, cosmetic, chemical, and food applications.

Constructed from premium-grade stainless steel SS316L, SS316, SS304L & SS304 the mixer features a variable-speed motor to adapt to a range of viscosities up to 80,000 cps. Its removable mixing head and straightforward design ensure hassle-free cleaning and maintenance, maximizing uptime and process reliability in demanding batch production environments. Ergonomic Manual Lifting for Flexible, Safe Operation.

Models & Data Sheet

| Model | Motor Power (HP) | Rotation Speed @ 50 Hz (RPM) | Suggested Capacity (L) |

| BHM-1 | 1 | 3000 | <50 |

| BHM-2 | 2 | 3000 | <75 |

| BHM-3 | 3 | 3000 | <100 |

| BHM-5 | 5 | 3000 | <200 |

| BHM-7.5 | 7.5 | 3000 | <300 |

| BHM-10 | 10 | 3000 | <500 |

| BHM-15 | 15 | 3000 | <750 |

| BHM-20 | 20 | 1500/3000 | <1000 |

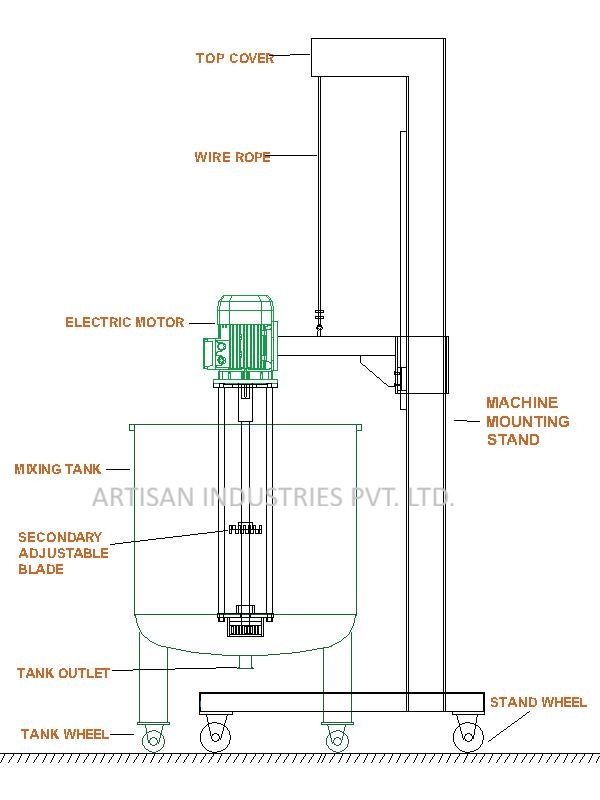

2D Design & Drawing

Specification

- Model Type: High Shear Batch Mixer – Manual Lifting

- Mixing Speed: Up to 2880 RPM (variable as per model)

- Motor Power: 1 HP to 20 HP (depending on tank capacity and application)

- Material of Construction: SS304 / SS316 Contact Parts

- Mixing Capacity: 5 to 500 liters (customizable)

- Lifting Mechanism: Manual lifting system for easy positioning of the mixer head

- Power Supply: 415V, 50/60 Hz, Three Phase

- Rotor–Stator Assembly: Precision-engineered for uniform particle size reduction

- Mounting Type: Heavy-duty base frame with adjustable height

- Surface Finish: Mirror-polished contact parts and painted frame

Key Features

- Manual Lifting System – Enables easy up-and-down movement of the mixing head to suit different vessel sizes.

- Interchangeable Rotor–Stator Assembly – Allows quick cleaning, maintenance, and configuration changes for various applications.

- Compact & Portable Design – Ideal for laboratory, pilot-scale, and small batch production environments.

- Energy-Efficient Motor – Designed for continuous operation with stable performance and low power consumption.

- Robust Construction – Built with SS304 or SS316 stainless steel for superior corrosion resistance and hygiene.

Advantage

- Precision Rotor–Stator Design: Ensures ultra-fine particle reduction and superior emulsion stability for high-quality end products.

- Manual Lift with Lock Mechanism: Provides safe and precise height adjustment, allowing flexibility for various vessel sizes.

- Variable Frequency Drive (VFD) Option: Enables smooth speed control for different mixing viscosities and batch requirements.

- Optimized Flow Circulation: Advanced fluid dynamics design enhances product uniformity and reduces processing time.

- Easy Maintenance System: Quick disassembly of mixing head and smooth surfaces allow hassle-free cleaning and reduced downtime.

Application

- Pharmaceutical Industry: Preparation of creams, ointments, suspensions, and syrups with uniform texture and particle size.

- Cosmetic Industry: Blending of lotions, gels, emulsions, and shampoos for smooth, stable formulations.

- Food Industry: Emulsification and dispersion of sauces, dressings, and flavorings to achieve consistent taste and texture.

- Chemical Industry: Mixing of paints, resins, detergents, and specialty chemicals requiring high shear processing.

- Adhesives & Coatings: Ensures uniform dispersion of pigments and additives for smooth, high-quality finishes.

Other Stator (Head) Options

Slot Type Head

Mesh Type Head

General Purpose Holes Type Head

You Might Also Like ………………………..<>