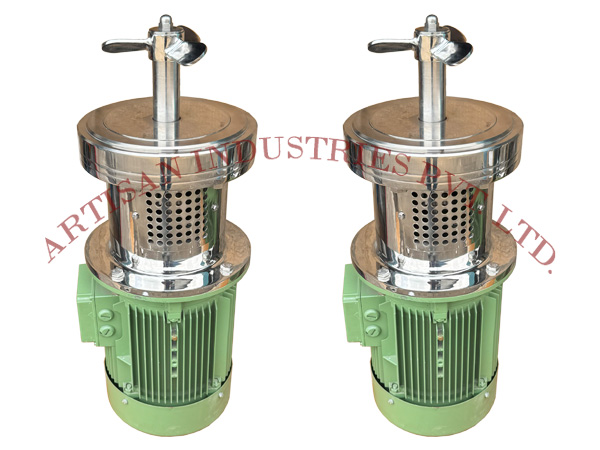

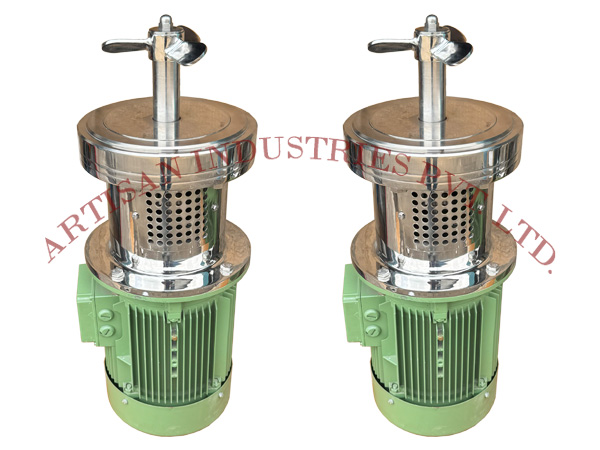

Bottom Entry Stirrer

Artisan Bottom Entry Stirrer is engineered for efficient mixing, dispersion, and homogenization directly from the base of the tank, ensuring excellent circulation and uniform results. Positioned at the bottom, it creates upward flow patterns that eliminate dead zones and improve product consistency. Manufactured with premium stainless steel grades such as SS304 and SS316, it offers superior durability, corrosion resistance, and hygienic operation. Its compact design saves space, reduces vibration, and enhances mixing efficiency while maintaining ease of installation and maintenance.

Widely used in industries like pharmaceuticals, food, beverages, cosmetics, and chemicals, this stirrer is ideal for blending, dissolving, and maintaining suspensions. Its reliable performance, energy-efficient operation, and adaptability to different viscosities make it a versatile and cost-effective solution for continuous and batch processing.

Models & Data Sheet

| Model | Motor Power (HP) | Rotation Speed @ 50 Hz (RPM) | Suggested Capacity (L) |

| BES-1 | 1 | 1500 | <100 |

| BES-2 | 2 | 1500 | <200 |

| BES-3 | 3 | 1500 | <300 |

| BES-5 | 5 | 1500 | <500 |

| BES-7.5 | 7.5 | 1500 | <7.5 |

| BES-10 | 10 | 1500 | <1000 |

| BES-15 | 15 | 1500 | <1500 |

| BES-20 | 20 | 1000/1500 | <2000 |

| BES-25 | 25 | 1000/1500 | <2500 |

| BES-30 | 30 | 1000/1500 | <3000 |

| BES-40 | 40 | 1000/1500 | <4000 |

| BES-50 | 50 | 1000/1500 | <5000 |

Specifications & Key Features

- Motor Power (range) — Available from 1 HP to 75 HP+, suitable for small to large industrial tanks.

- Speed Range — Variable speed control from 20–1500 RPM using VFD for precise stirring of low- to high-viscosity fluids.

- Bottom-Entry Shaft & Impeller — Stainless-steel shaft with interchangeable impellers (propeller, turbine, anchor, pitched blade) for versatile mixing.

- Mounting & Installation — Flanged or clamp-on bottom-mount design for tank integration; supports retrofitting in existing tanks.

- High-Torque Gearbox — Helical or planetary gearbox options for high-viscosity mixing at low speeds.

- Seal Options — Mechanical seals, stuffing box, or magnetic coupling for leak-proof operation and sanitary applications.

- Wetted Parts Material — SS304/SS316 with optional sanitary polish or coated finish for chemical, food, and pharmaceutical use.

- Control & Safety Features — Integrated panel with start/stop, VFD, emergency stop, torque monitoring, and interlocks for operator safety.

- Maintenance & Serviceability — Modular design with easy access to bearings, seals, and impellers for reduced downtime.

- Applications & Performance — Ideal for blending, emulsifying, and homogenizing in paints, coatings, adhesives, chemicals, cosmetics, and food/pharma industries; suitable for low- and high-viscosity fluids with minimal vortex formation.

Advantages

- High-efficiency mixing — Ideal for low- to high-viscosity fluids with uniform blending and reduced processing time.

- Direct bottom mounting — Saves tank top space and integrates easily into existing setups.

- Powerful torque & speed control — VFD and high-torque gearbox allow precise agitation at all speeds.

- Durable & low-maintenance — Stainless-steel wetted parts, modular design, and accessible components ensure long service life.

- Versatile applications — Suitable for blending, emulsification, and homogenization across paints, chemicals, adhesives, cosmetics, and food/pharma industries.

Applications

- Paints & Coatings — Uniform dispersion of pigments, fillers, and resins for consistent product quality.

- Adhesives & Sealants — Effective blending of polymers, thickeners, and additives for stable formulations.

- Chemicals & Petrochemicals — Efficient mixing of emulsions, suspensions, and polymer solutions in large tanks.

- Cosmetics & Personal Care — Homogenizing creams, lotions, gels, and emulsions with smooth texture.

- Food & Pharmaceuticals — Hygienic mixing of sauces, syrups, and liquid formulations for consistent quality.