Bottom Entry Homogenizer

Artisan Bottom Entry Homogeniser is engineered to provide powerful mixing, emulsifying, and homogenizing directly from the base of your vessel. Positioned at the bottom, the high shear head ensures efficient circulation and rapid breakdown of particles, creating smooth, uniform, and stable mixtures. This design minimizes air incorporation, making it ideal for applications where product clarity and consistency are essential, such as in food, beverage, cosmetics, and pharmaceutical production.

Built with robust materials and precision components, the Bottom Entry Homogeniser delivers reliable performance with reduced processing times. Its compact design allows seamless integration into new or existing tanks, while easy access ensures straightforward cleaning and maintenance. Offering efficiency, durability, and exceptional mixing quality, this solution is perfect for businesses seeking consistent results with a space-saving configuration.

Models & Data Sheet

| Model | Motor Power (HP) | Rotation Speed @ 50 Hz (RPM) | Suggested Capacity (L) |

| BEH-1 | 1 | 3000 | <50 |

| BEH-2 | 2 | 3000 | <75 |

| BEH-3 | 3 | 3000 | <100 |

| BEH-5 | 5 | 3000 | <200 |

| BEH-7.5 | 7.5 | 3000 | <300 |

| BEH-10 | 10 | 3000 | <500 |

| BEH-15 | 15 | 3000 | <750 |

| BEH-20 | 20 | 1500/3000 | <1000 |

| BEH-30 | 30 | 1500/3000 | <1500 |

| BEH-40 | 40 | 1500/3000 | <2000 |

| BEH-50 | 50 | 1500/3000 | <3000 |

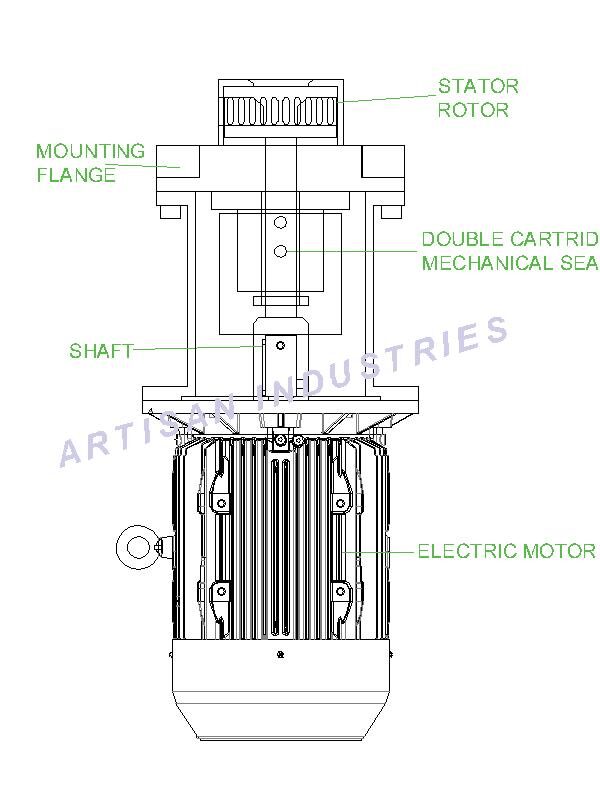

2D Design & Drawing

Specifications & Key Features

- High Shear Performance – Delivers intense mixing, dispersion, and emulsification directly at the vessel bottom for superior product uniformity.

- Compact Bottom-Mounted Design – Saves space and ensures efficient circulation with minimal dead zones in the mixing vessel.

- Rotor–Stator Technology – Precision-engineered rotor–stator assembly provides consistent particle and droplet size reduction.

- Material of Construction – Available in SS304 or SS316/SS316L for compatibility with pharmaceutical, cosmetic, and food-grade applications.

- Motor Power Range – Customizable from 1 HP to 50 HP depending on process volume and viscosity.

- Speed & Control – Operates at variable speeds up to 3000 RPM for flexible process control and energy efficiency.

- Sealing Options – Fitted with mechanical seals or double cartridge seals for safe operation under pressure or vacuum conditions.

- Ease of Integration – Designed for use in process vessels, reactors, or mixing tanks for batch and continuous operations.

- Low Maintenance Design – Robust construction with quick access to the rotor–stator assembly for easy cleaning and servicing.

- Wide Application Range – Ideal for emulsions, suspensions, creams, gels, lotions, and other viscous formulations across industries.

Advantages

- Efficient Mixing Performance: Ensures rapid dispersion and uniform blending directly at the vessel base for faster processing.

- Space-Saving Design: Compact bottom-mounted setup ideal for tanks with limited headroom.

- Improved Product Consistency: Delivers superior homogenization with minimal air incorporation.

- Easy Maintenance & Cleaning: Simple access for cleaning and CIP/SIP compatibility ensures hygiene.

- Energy Efficient Operation: Optimized rotor–stator design minimizes energy consumption while maximizing shear efficiency.

Applications

- Pharmaceutical Industry: Used for preparing creams, ointments, gels, and suspensions with uniform texture.

- Cosmetic & Personal Care: Ideal for emulsifying lotions, conditioners, serums, and other skincare formulations.

- Food & Beverage Processing: Suitable for homogenizing sauces, dressings, dairy products, and flavor emulsions.

- Biotech & Laboratory Use: Used in sample preparation, cell disruption, and small-scale formulation development.