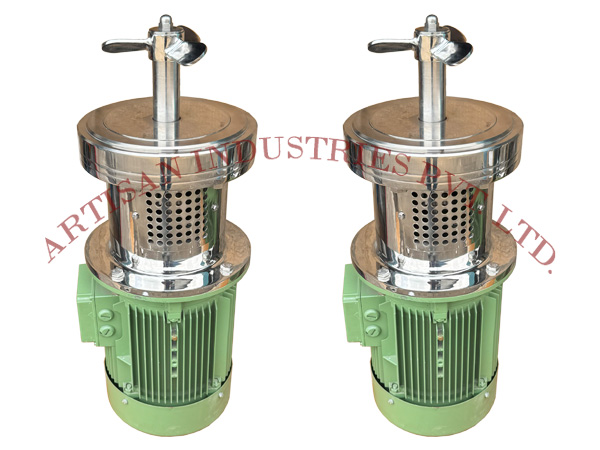

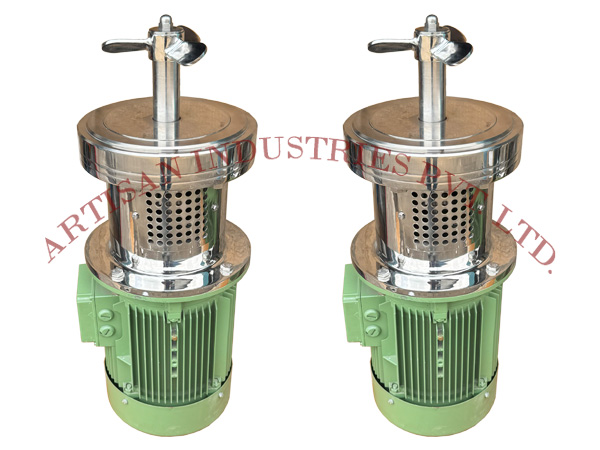

Side Entry Mixer

Artisan Side Entry Stirrer is designed for efficient mixing, blending, and homogenization in large tanks and vessels, especially where top or bottom entry is not feasible. Mounted horizontally from the side, it ensures excellent circulation by creating strong flow patterns that prevent sedimentation and maintain uniform product consistency. Built with premium stainless steel grades like SS304 and SS316, it delivers durability, hygiene, and corrosion resistance. Its design also ensures low power consumption while maximizing mixing efficiency.

Commonly used in industries such as pharmaceuticals, food, beverages, chemicals, and water treatment, this stirrer is perfect for suspension, dilution, and heat transfer processes. With easy maintenance, energy efficiency, and reliable performance, the Side Entry Stirrer offers a cost-effective solution for large-scale mixing requirements.

Models & Data Sheet

| Model | Motor Power (HP) | Rotation Speed @ 50 Hz (RPM) | Suggested Capacity (L) |

| SEM-1 | 1 | 1500 | <30 |

| SEM-2 | 2 | 1500 | <75 |

| SEM-3 | 3 | 1500 | <120 |

| SEM-5 | 5 | 1500 | <200 |

| SEM-7.5 | 7.5 | 1500 | <400 |

| SEM-10 | 10 | 1500 | <500 |

| SEM-15 | 15 | 1500 | <750 |

| SEM-20 | 20 | 1000/1500 | <1000 |

| SEM-25 | 25 | 1000/1500 | <1500 |

| SEM-30 | 30 | 1000/1500 | <2000 |

| SEM-40 | 40 | 1000/1500 | <4000 |

| SEM-50 | 50 | 1000/1500 | <5000 |

Specifications & Key Features

- Motor Power (range) — Available from 1 HP to 100 HP+, suitable for small to large industrial tanks.

- Speed Range — Variable speed control from 10 to 500 RPM, adjustable for low- to high-viscosity fluids.

- Side-Entry Shaft & Impeller — Stainless-steel shaft with high-efficiency impellers (propeller, hydrofoil, or anchor) for uniform mixing.

- Mounting & Installation — Flanged or bracket-mounted design allows installation on tank side walls, reducing floor space usage.

- Wetted Parts Material — SS304/SS316 stainless steel or optional sanitary finish for chemical, food, and pharma applications.

- Seal Options — Mechanical seals, stuffing box, or magnetic coupling available for leak-proof operation.

- Hydraulic or Manual Adjustment — Optional lifting/lowering mechanism for precise impeller positioning inside tanks.

- Control & Safety Features — Integrated panel with start/stop, VFD speed control, emergency stop, and overload protection.

- Maintenance & Serviceability — Easy access to bearings, seals, and impellers for minimal downtime and low maintenance costs.

- Applications & Performance — Ideal for blending, homogenizing, and circulation of liquids in chemicals, paints, coatings, adhesives, food, and pharmaceuticals; ensures efficient mixing with minimal vortexing.

Advantages

- Space-saving design — Installs on tank sides, freeing floor space and allowing retrofitting in existing tanks.

- Efficient low-speed mixing — Ideal for high-viscosity liquids, suspensions, and shear-sensitive materials.

- Precise impeller positioning — Manual or hydraulic adjustment ensures uniform mixing and optimal flow patterns.

- Durable, low-maintenance construction — Stainless-steel wetted parts and accessible components reduce downtime.

- Versatile applications — Suitable for chemical, paint, adhesive, food, and pharmaceutical industries.

Applications

- Chemicals & Solvents — Homogenizing, blending, and maintaining uniformity in high-viscosity chemical tanks.

- Paints & Coatings — Efficient circulation and dispersion of pigments, fillers, and resins for consistent quality.

- Adhesives & Sealants — Mixing polymers, thickeners, and additives to achieve uniform bonding properties.

- Food & Beverage — Gentle mixing of sauces, syrups, and liquid ingredients without aeration.

- Pharmaceuticals & Cosmetics — Ensures smooth blending of creams, lotions, and sanitary liquid formulations..